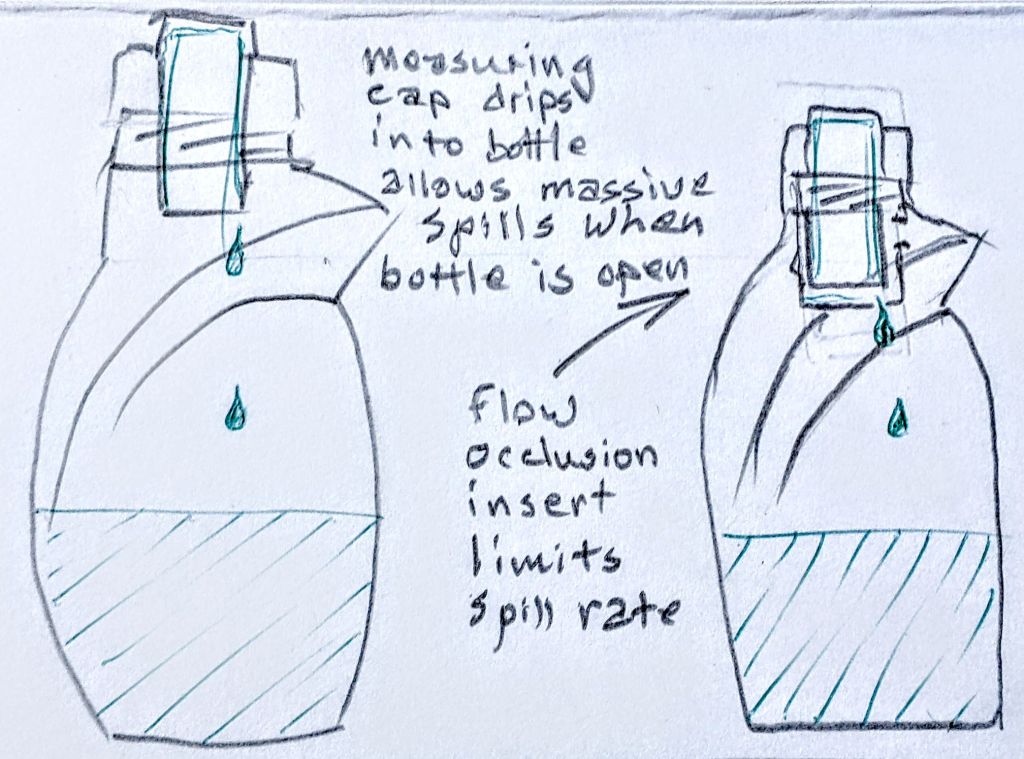

The consumer-size bottle of Roundup has a measuring cap. It is designed to drip back into the bottle after use. Good idea, except…

When the cap is removed, a wide mouth is revealed. So it’s possible to spill the entire contents of the bottle in an instant. This is (sorry for the technical language) “bad”. Since the consumer only needs a few ounces at a time, it would make sense to limit the flow rate somehow. But how, while still having the measuring cap? The bottle is blow-molded, so the opening can’t easily have secondary passages or fittings.

How about if they add a snap-in flow-limiting insert, so it would take, say, several seconds to pour out one capful. This would limit the severity of spills. The insert could be injection molded, adding about a penny to the cost of the bottle. It would have a small drain hole at the bottom, and a slightly larger emptying hole near the top just under the snap joint. If the emptying hole were on just one side of the wide axis, even a long-duration spill could not exceed half the volume of the bottle.

It might be necessary to slightly alter the curvature of the bottle to make up for lost volume. This would not increase the shipping or shelf size, and as a bonus would make the bottle less apt to tip.